These skates were started in a panic the last time I moved my shop. I had less than a month to find a new shop and move in San Francisco. This is not an easy task. Needless to say I did not finish them in time for the move.

I generally make shop items from whatever I have in the shop. It this case, what I had in the shop changed over the years. Honestly, if I started this now I would have just bought some skates from Amazon. The price has really come down and there are a lot more options. But I started this and I wanted to finish it.

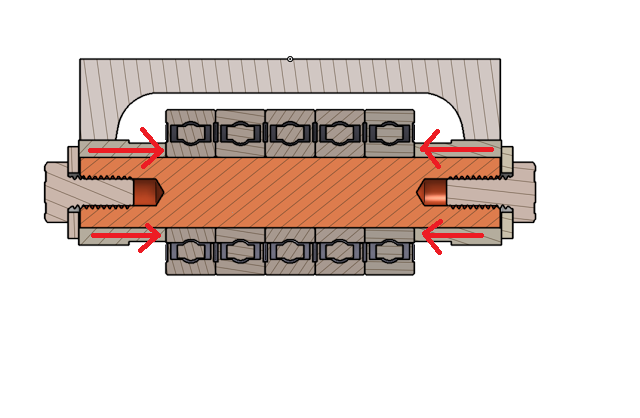

My design involved a c-channel and some cheap bearings from ebay. I weld some mounts onto the c-channel to squeeze the inner races of the bearings. This properly distributes the load. They are smooth as butter. It has been several years and I cannot remember the actual forces these can hold. I sure it somewhere around a shit ton.

Unfortunately I made the axles from pretty hard steel. I am not sure what steel it was as I made these serval years ago. They were difficult to tap. I did not want to break a tap so I tapped them by hand.

Machining of the axle blocks and c-channels.

Tacking the axel blocks.

Tacking the handle loop. The rods were some old grounding rod, hence the copper plating.

Making the handle. This was an afterthought.

The angle on the handle looks good!

I painted it antique white with accents of anti seize. I am ready to move again!

Thanks for looking! There are more pics, CAD, and CAM here...

If you need some design and build help on your project, don't hesitate to give us a call!